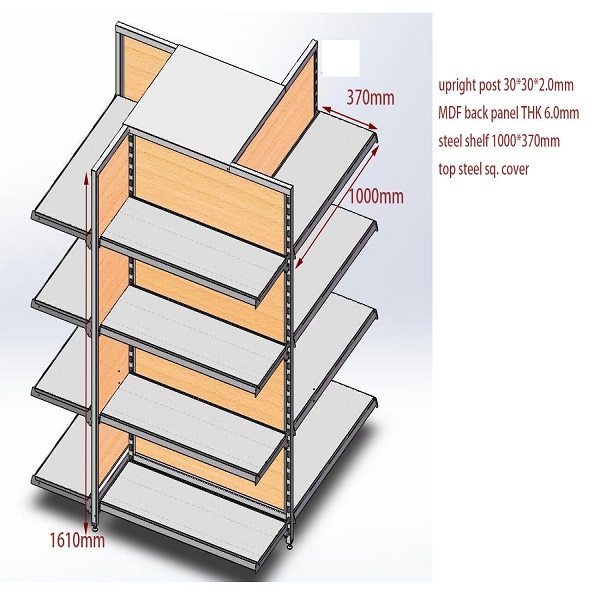

Factory directly provided Double side shelving to Liberia Factories

Short Description:

Suzhou Innovative Store Equipment Co., Ltd – Manufacturing of shelf systems for shop fittings ( shop shelving, retail shelving, display shelving, storage shelving, warehouse shelving ) was started in the 1989’s. Because of improvement in products quality and achievement of compatibility with another used shelf systems, production strongly expanded both in total output and quantity of manufactured components parts. We are willing to offer you a solution for any problem in the area of shopfitti...

Factory directly provided Double side shelving to Liberia Factories Detail:

Suzhou Innovative Store Equipment Co., Ltd – Manufacturing of shelf systems for shop fittings ( shop shelving, retail shelving, display shelving, storage shelving, warehouse shelving ) was started in the 1989’s. Because of improvement in products quality and achievement of compatibility with another used shelf systems, production strongly expanded both in total output and quantity of manufactured components parts.

We are willing to offer you a solution for any problem in the area of shopfitting. We can offer both our standard products and products meeting your specific requirements.

Everything will be delivered in perfect shape and high quality.

Standard components

- Double sided gondola provide maximum merchandising capacity for your store

- Heavy duty slotted uprights and base supports make shelving unit stable

- Base shelf made of rugged 0.8mm steel

- Attractive powder coating finish

- Back panel made of 1.2mm steel panel with standard 1” centered holes

- Back panel made of 0.9mm steel panel with slot channel

- Back panel made of 0.7mm steel flat panel

- Back panel made of 6mm MDF with standard 1” center holes

| Upright | H 1210 – 3010mm |

| Base support | 200mm | 270mm | 300mm | 370mm | 470mm | 570mm | 670mm | 770mm |

| Steel shelf | W 665mm | 800mm | 1000mm | 1200mm | 1220mm | 1250mm | 1330mmD 200mm | 270mm | 300mm | 370mm | 470mm | 570mm | 670mm | 770mm |

| Back panel | W 665mm | 800mm | 1000mm | 1200mm | 1220mm | 1250mm | 1330mmH 100mm | 200mm | 300mm | 400mm | 500mm |

| Colors | Ral 9001 | Ral 9010 | Ral 7035 | Ral 9006 |

| Load Capa. (kgs) | 100kgs – - - 150kgs |

Advantage

- Easy set up with no tools required

- Designed to conserve warehouse space

- Industry’s most competitively priced units

- Designed to get attention and give maximum display space

More option

Use our optional parts and accessories to create a unique point-of-purchase units.

Peg hooks | Wire slatwall shelves | Light box | Timber shelves | Side frame | Side mirror panel | Wire cage | Spreader bar

What we can offer:

- System solution for any kind of shop centers

- High flexibility

- Simplicity and favourable price

- High quality

- Development and design according to requirements of clients

Product detail pictures:

Related Product Guide:

Flexible Financing With Mezzanine Debt

Why Choose Us for CU Racking

Factory directly provided Double side shelving to Liberia Factories, The product will supply to all over the world, such as: , , ,

I use this stuff on anything with rust on it. I don’t even use a wire brush on it and you can see how good looking the end result is. It will surprise you how much coverage you get with this stuff. It reads that two coats are better than one but one does the job great for me.

In this video I show you the Buy ClosetMaid 6222 Hanging Basket for Wire Shelving Home amp; Kitchen – ✓ FREE DELIVERY. For more details please visit: https://po.st/kdeK75 Thank You!

Great ClosetMaid 6222 Hanging Basket for Wire Shelving Review

ClosetMaid 6222 Hanging Basket for Wire Shelving Test

ClosetMaid 6222 Hanging Basket for Wire Shelving Unboxing

Review ClosetMaid 6222 Hanging Basket for Wire Shelving Hands-on

https://www.youtube.com/watch?v=_NUXtq5KD-E