New Arrival China Integrated display shelving to South Korea Factories

Short Description:

Suzhou Innovative Store Equipment Co., Ltd – Manufacturing of shelf systems for shop fittings ( hypermarket shelving, integrated display shelving, shop shelving, retail shelving, display shelving, storage shelving, warehouse shelving ) was started in the 1989’s. Because of improvement in products quality and achievement of compatibility with another used shelf systems, production strongly expanded both in total output and quantity of manufactured components parts. We are willing to offer you ...

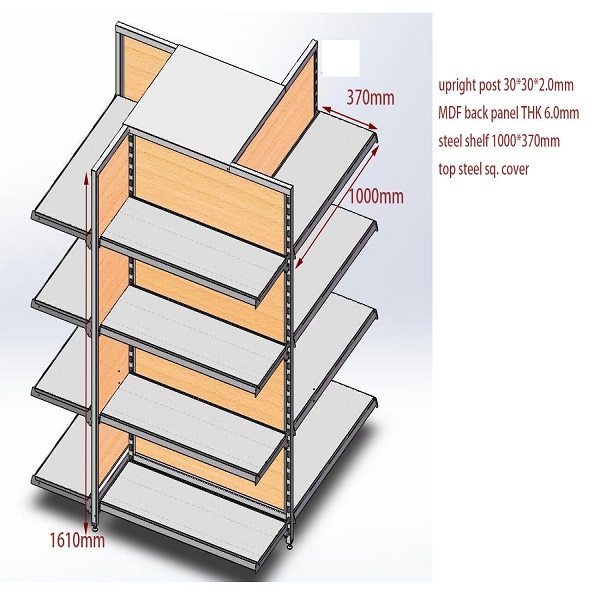

New Arrival China Integrated display shelving to South Korea Factories Detail:

Suzhou Innovative Store Equipment Co., Ltd – Manufacturing of shelf systems for shop fittings ( hypermarket shelving, integrated display shelving, shop shelving, retail shelving, display shelving, storage shelving, warehouse shelving ) was started in the 1989’s. Because of improvement in products quality and achievement of compatibility with another used shelf systems, production strongly expanded both in total output and quantity of manufactured components parts.

We are willing to offer you a solution for any problem in the area of shopfitting. We can offer both our standard products and products meeting your specific requirements.

Everything will be delivered in perfect shape and high quality.

Standard components

- Hypermarket shelving combine storage and display in one

- Enhance your department’s appearance and create a ‘customer friendly’ atmosphere with these integrated shelving units

- Attractive surface finish

- Back panel made of 1.2mm steel panel with standard 1” centered holes

- Back panel made of 0.7mm steel flat panel

- Back panel made of wire panel with 25*50mm grid

| Upright frame | H 2200 – 3400mmD 568mm | 668mm | 768mm | 860mm | 1060mm |

| Upright section | 80*70*2.0mm40*55*2.0mm |

| Beam | L 1330mm | 2000mm | 2500mm | 2660mm |

| Beam type | CC BEAM | STEP BEAM | CHANNEL BEAMTUBE BEAM |

| Colors | White | Black | Hammered grey |

| Load Capa. (kgs) | Above 1000kgs |

Advantage

- Designed to conserve warehouse and display space

- Industry’s most competitively priced units

- Designed to get attention and give maximum display space

More option

Use our optional parts and accessories to create a unique point-of-purchase units.

Peg hooks | Light box | Side panel

What we can offer:

- System solution for any kind of shop centers

- High flexibility

- Simplicity and favourable price

- High quality

- Development and design according to requirements of clients

Product detail pictures:

Related Product Guide:

Flexible Financing With Mezzanine Debt

Why Choose Us for CU Racking

New Arrival China Integrated display shelving to South Korea Factories, The product will supply to all over the world, such as: , , ,