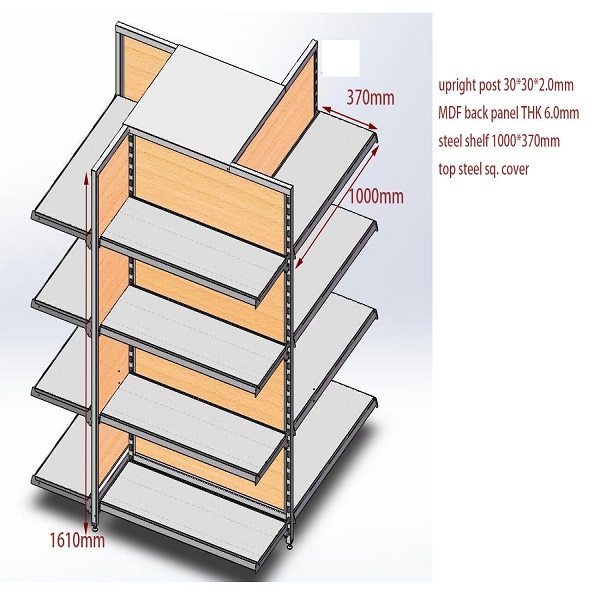

2017 China New Design Medium duty steel shelf racking Export to Saudi Arabia

Short Description:

Suzhou Innovative Store Equipment Co., Ltd. – the supplier of industrial warehouse shelving systems of the highest standard. Industrial shelving calls for high standards of stability and load bearing capacity and the optimum degree of safety. The warehouse racking provide is with speed and ease of assembly. The components parts can be straightforwardly assembled and are distinguished by the precision detailing of their cross members (with varying load bearing capacities) stretchers and shelve...

2017 China New Design Medium duty steel shelf racking Export to Saudi Arabia Detail:

Suzhou Innovative Store Equipment Co., Ltd. – the supplier of industrial warehouse shelving systems of the highest standard. Industrial shelving calls for high standards of stability and load bearing capacity and the optimum degree of safety. The warehouse racking provide is with speed and ease of assembly. The components parts can be straightforwardly assembled and are distinguished by the precision detailing of their cross members (with varying load bearing capacities) stretchers and shelves.

Safety is a major feature of our industrial shelving systems. Indispensable safety accessories include end-brackets, back stops and collision guards. Environmental protection is closely associated with safety. Our powder coating contain no solvents, while the process materials we use are free of any aromatic or chlorinated hydrocarbons.

Standard components

- TG pallet racking make the warehouse neat & clean

- Save time and money with the easy to assemble Pallet Rack System.

- Frames and beams are fabricated from heavy material

- Holes on back of column make the surface flat and nice

- Connector safety lock provide auto engagement, resist dislodgement and is removable and save

- Different types of beam and shelves is fit for different packaging

- Standard color of frame is vista green, beams are poppy orange

| Upright frame | H 2200 – 5000mmD 400mm – 1050mm |

| Upright section | 40*55*2.0mm80*70*2.0mm

90*70*2.0mm |

| Beam | L 1200mm – 3000mm |

| Beam type | CC BEAM | STEP BEAM | CHANNEL BEAM | TUBE BEAM |

| Colors | White | Orange | Blue |

| Load Capa. (kgs) | Above 2500kgs |

Advantage

- Designed to conserve warehouse and display space

- Industry’s most competitively priced units

- Designed to get attention and give maximum display space

More option

Use our optional parts and accessories to create a unique point-of-purchase units.

Storage wire cage | Corner guard | Column protector | Frame protector | Pallet stopper | Side wire mesh panel | Advertise top panel | Light box

What we can offer:

- System solution for any kind of storage and warehouse

- High flexibility

- Simplicity and favourable price

- High quality

- Development and design according to requirements of clients

Product detail pictures:

Related Product Guide:

Ideas for Recessed Room Shelves

Wire Shelving: A Do It Yourself Space Saving Solution

2017 China New Design Medium duty steel shelf racking Export to Saudi Arabia, The product will supply to all over the world, such as: , , ,