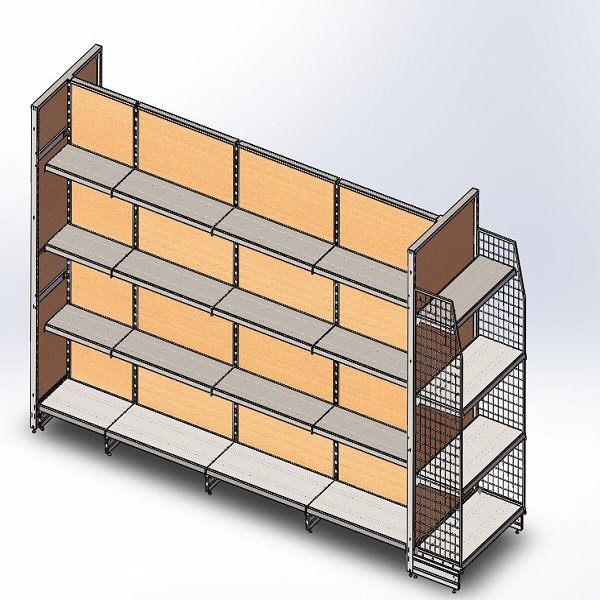

Chinese wholesale AU50 outrigger shelving for Adelaide Manufacturer

Short Description:

Suzhou Innovative Store Equipment Co., Ltd – Manufacturing of shelf systems for shop fittings ( shop shelving, retail shelving, display shelving, storage shelving, warehouse shelving ) was started in the 1989’s. Because of improvement in products quality and achievement of compatibility with another used shelf systems, production strongly expanded both in total output and quantity of manufactured components parts. We are willing to offer you a solution for any problem in the area of shopfitti...

Chinese wholesale AU50 outrigger shelving for Adelaide Manufacturer Detail:

Suzhou Innovative Store Equipment Co., Ltd – Manufacturing of shelf systems for shop fittings ( shop shelving, retail shelving, display shelving, storage shelving, warehouse shelving ) was started in the 1989’s. Because of improvement in products quality and achievement of compatibility with another used shelf systems, production strongly expanded both in total output and quantity of manufactured components parts.

We are willing to offer you a solution for any problem in the area of shopfitting. We can offer both our standard products and products meeting your specific requirements.

Everything will be delivered in perfect shape and high quality.

Standard components

- AU50 Outrigger shelving with heavy duty capacity to hold bottled heavy commodities

- Heavy duty slotted upright frames and base supports make ‘H’ shelving unit stable

- Chrome shelves with wire grid

- Attractive surface finish

- Back panel made of 0.8mm steel panel with standard 1” centered holes

- Back panel made of 1.0mm steel panel with standard 1” centered volcano holes

- Back panel made of 0.6mm steel flat panel

- Back panel made of wire panel with 25*50mm grid

| Upright with base support | H 2250 – 2400mmD 305mm | 355mm | 405mm | 455mm | 505mm |

| Chrome wire shelf | W 900mmD 305mm | 355mm | 405mm | 455mm | 505mm |

| Back panel | W 900mmH 2121mm | 2271mm |

| Colors | White | Black | Hammered grey |

| Load Capa. (kgs) | 150kgs |

Advantage

- Easy set up with no tools required

- Designed to conserve warehouse space

- Industry’s most competitively priced units

- Designed to get attention and give maximum display space

More option

Use our optional parts and accessories to create a unique point-of-purchase units.

Peg hooks | Light box | Side frame | Side mirror panel | Spreader bar

What we can offer:

- System solution for any kind of shop centers

- High flexibility

- Simplicity and favourable price

- High quality

- Development and design according to requirements of clients

Product detail pictures:

Related Product Guide:

Wooden Kitchen Shelves Offer Beauty and Versatility

Why Choose Us for CU Racking

Chinese wholesale AU50 outrigger shelving for Adelaide Manufacturer, The product will supply to all over the world, such as: , , ,

This is a nearly completed laser cutter project built on the chassis of a $15 desk found on Craigslist. The heart of the project started as a 75% complete group of parts that I also scored on CL for $520. This included: the XY frame, steppers, Gecko G540, optics, and 40W laser tube & P/S, water pump, radiator, and honeycomb. I bought the desk on 9/10/2013 and started cutting & welding. Today is 10/1, so basically 3 weeks of tinkering was involved with this project.

The frame’s X axis had a bit of wobble, so I bought a THK linear rail to beef up and smooth out the right hand side (another $75 / Ebay). The gantry is now very stable. I bought about $80 worth of leadscrew, acme nuts, sprockets and #25 chain to build a manual Z axis. This was from Surplus Center in Nebraska, an A+ outfit.

Other misc purchases were about $20 of 80-20 T-slot AL to mount the tube on, $100 worth of misc hardware like the plexiglass lid, piano hinge, angle iron for the frame (which is welded), and $8 for a water flow sensor. The bottom of the box is thick sheet metal scrap that I had laying around, and the sidewalls are made from black laminated MDF shelving that I found in the scratch and dent pile for $1.50 each x 2. I bought a beefier Y axis stepper for $25 since the gantry is now a bit heavier than the original stock design. I slipped in at around $900 total for everything, but that does not include some things I already had, like the FanTech fan, airbrush pump, Thorlabs optical mounts, 24V PSU, cables, Igus chain, etc… (it’s good to be a hoarder).

The people I would like to thank are: Aaron for giving me the smokin’ deal on the majority of the parts, Dan B for the great deal on the desk, and the following youtubers whose videos gave me some good ideas: Christopher Robinson, LPFThings, & Stephen Hobley- you guys may not know it, but your videos really helped me out!

-Mike