14 Years Factory wholesale Rolling wire shelving to Afghanistan Manufacturer

Short Description:

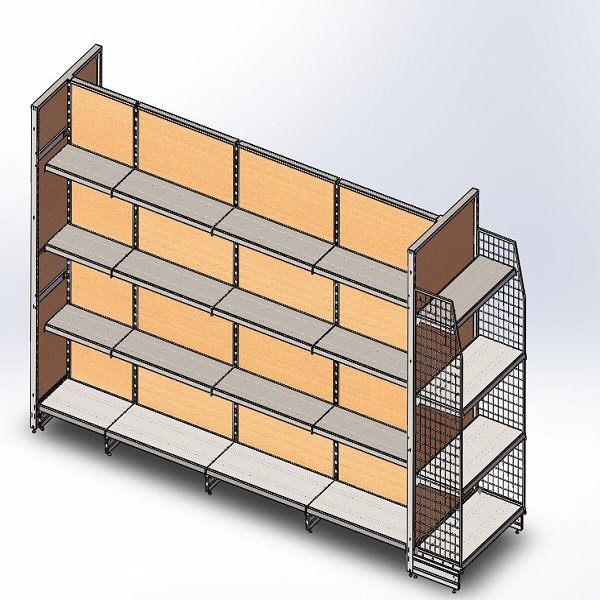

Suzhou Innovative Store Equipment Co., Ltd. – the supplier of Industrial Wire Shelving Racks. Our line of Industrial Wire Shelving Racks may be utilized in many applications ranging from display, storage, decoration, etc. Standard components Industrial Wire Shelving Rack easy assembly with no tool required 1” round post is with every 1” line Mid duty and heavy duty shelves are for choice Post H 35” | 48” | 63” | 70” | 79” | 86” Wire shelves W 36” | 48”D 14” | 18” | 24” Colors...

14 Years Factory wholesale Rolling wire shelving to Afghanistan Manufacturer Detail:

Suzhou Innovative Store Equipment Co., Ltd. – the supplier of Industrial Wire Shelving Racks.

Our line of Industrial Wire Shelving Racks may be utilized in many applications ranging from display, storage, decoration, etc.

Standard components

- Industrial Wire Shelving Rack easy assembly with no tool required

- 1” round post is with every 1” line

- Mid duty and heavy duty shelves are for choice

| Post | H 35” | 48” | 63” | 70” | 79” | 86” |

| Wire shelves | W 36” | 48”D 14” | 18” | 24” |

| Colors | PC surface | Zinc plated | Chrome plated |

| Load Capa. (kgs) | Above 100kgs |

Advantage

- Flexible design with adjustable shelves

- Industrial grade with chrome plated

- Quick assembly with no tools required

More option

Use our optional parts and accessories to create a unique point-of-purchase units.

T post | Side panel | MDF hole back | Side wire mesh panel | Spreader bar | Front door

What we can offer:

- System solution for any kind of storage and warehouse

- High flexibility

- Simplicity and favourable price

- High quality

- Development and design according to requirements of clients

Product detail pictures:

Related Product Guide:

Wire Shelving: A Do It Yourself Space Saving Solution

Why Choose Us for CU Racking

14 Years Factory wholesale Rolling wire shelving to Afghanistan Manufacturer, The product will supply to all over the world, such as: , , ,

54-second video demonstrating the features and benefits of Akro-Mils’ Steel Shelving Systems. These heavy-duty systems are ideal for storing and organizing heavy items!

More information on these products is available at https://akro-mils.com/Products/Types/Cabinets-Racks-Shelving-Panels/Steel-Shelving .

For more information contact Akro-Mils customer service at 800-253-2467.

https://www.akro-mils.com

https://www.myersindustries.com

© 2014 Akro-Mils® / Myers Industries, Inc.